FritsJurgens – Continuous improvement

FritsJurgens strives for the best possible quality. Every system that leaves the FritsJurgens headquarters is designed, fabricated, and tested with the greatest attention to detail and with only the best quality materials. This enabled us to create maintenance-free hinges: even after 136 years of daily use, the hinge will still function flawlessly. Every part of the production process contributes to the quality of the end result. Let us take you through the fabrication procedure of System M and System M+ and discover what gives these systems their durability.

Casing

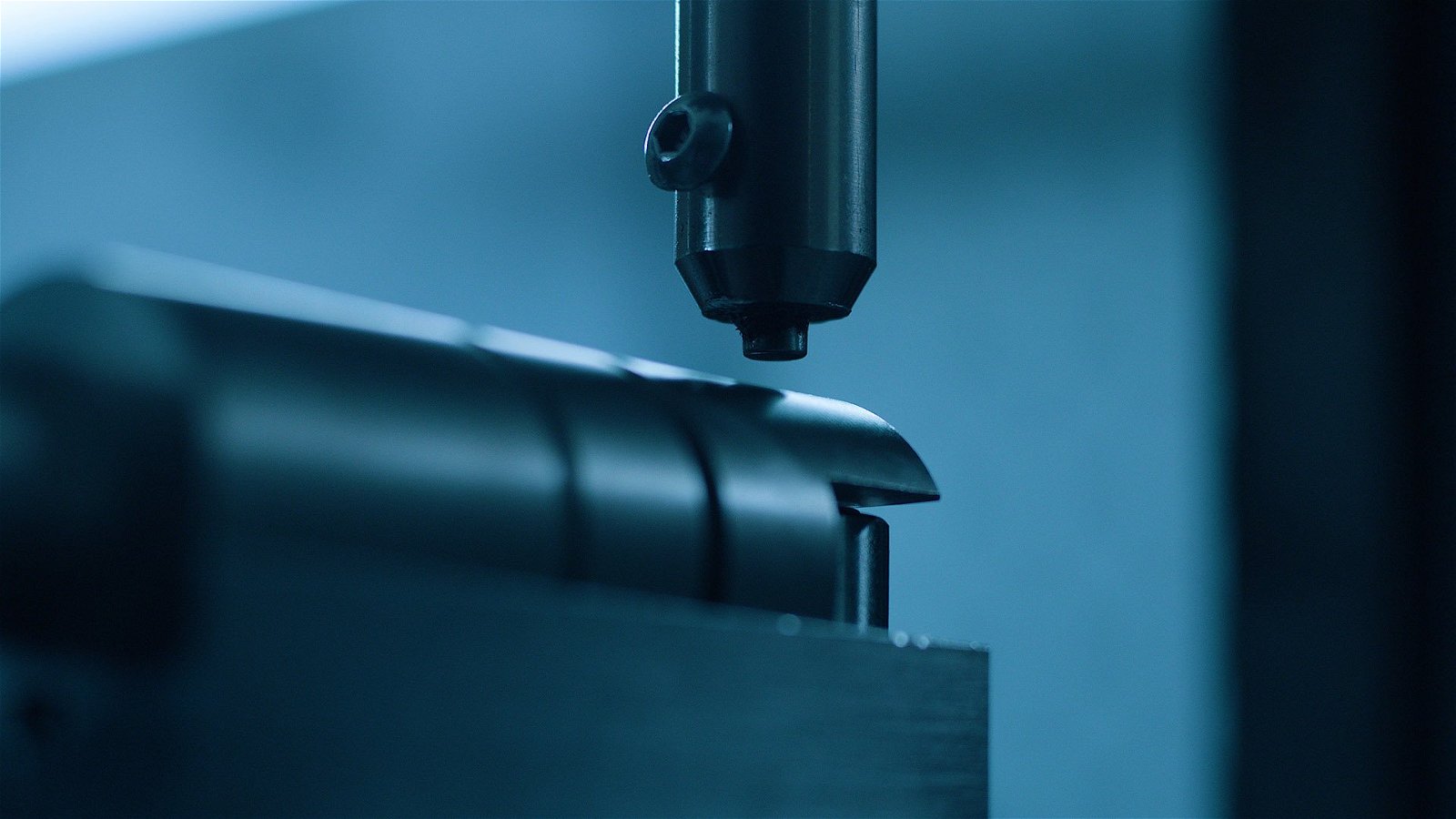

Every FritsJurgens pivot hinge is hidden inside the door. To be suitable for the minimum door thickness of 40 mm, the system and its casing have to be precisely 32 mm thick. The system has to carry and control doors that weigh up to hundreds of kilos and with extreme dimensions. This results in the challenge of putting a lot of technique and force into a compact space.

By using only the best materials and techniques, the durability of the system is ensured. The casing is created with a Japanese machine by Matsuura, which is known for its extreme precision. To harness the power the system has to endure, the casing is made out of one solid piece of aluminum. This means that there are as few connections as possible and no gaskets to prevent leaks or inaccuracies.

Brackets

The casing contains separate brackets. The shape of these brackets is being extruded out of a single piece of aluminum. Not a single part of the bracket is bent to prevent any internal stress in the material. Combined with a specified radius on the bracket, it provides the hinge the ultimate strength in every situation.

Highest corrosion resistance

The casing of the system is anodized. With this comes a protective, corrosion-resistant layer over every surface of the casing, inside and outside. This provides a stiffer and more wear-resistant finish, which is essential for all the system’s moving parts. System M and System M+ have a very high corrosion resistance: digit 5 in a range of 1-5 according to the EN1670 standard. Even the most diverse conditions do not affect the performance of these systems.

Pistons

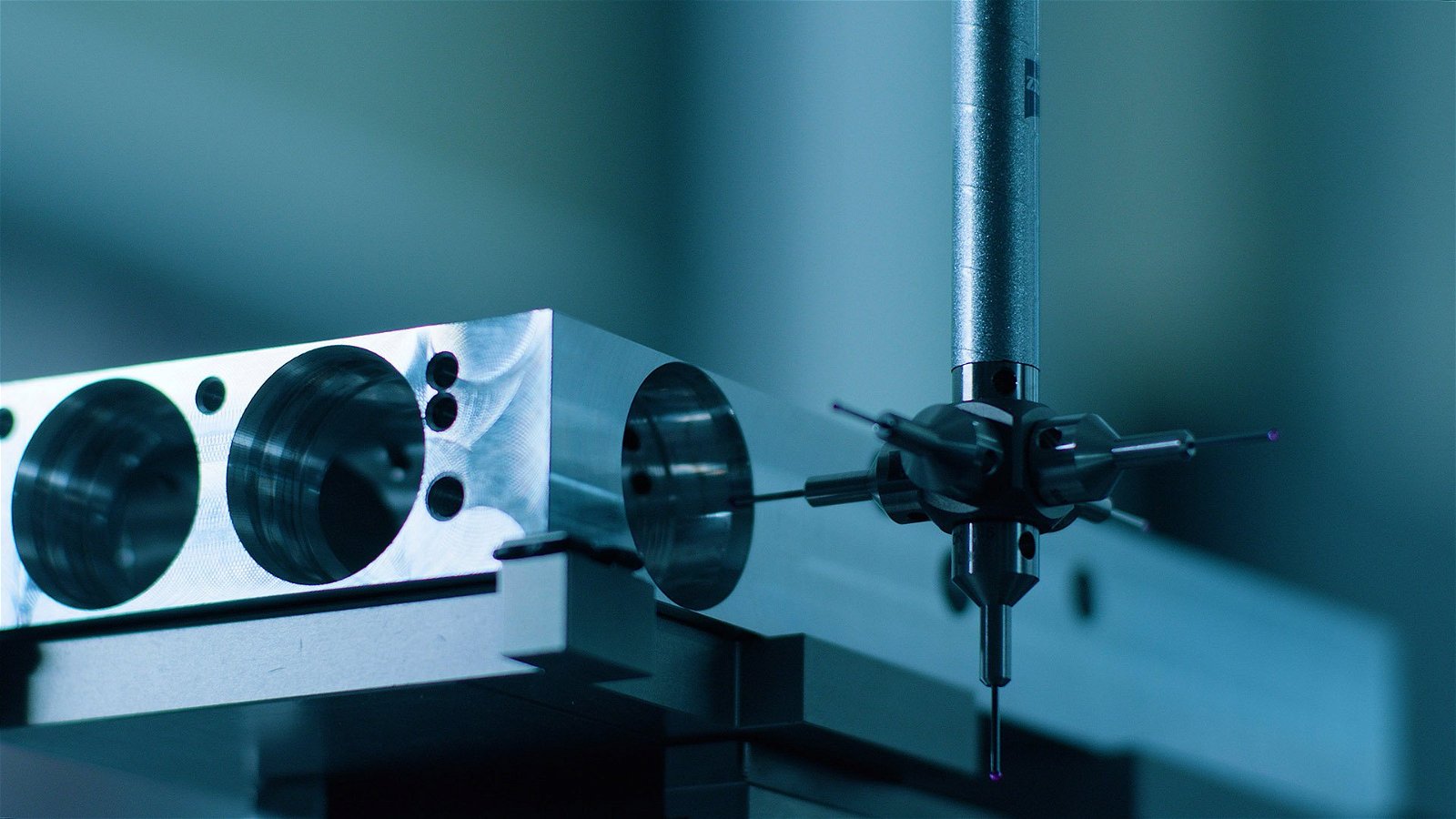

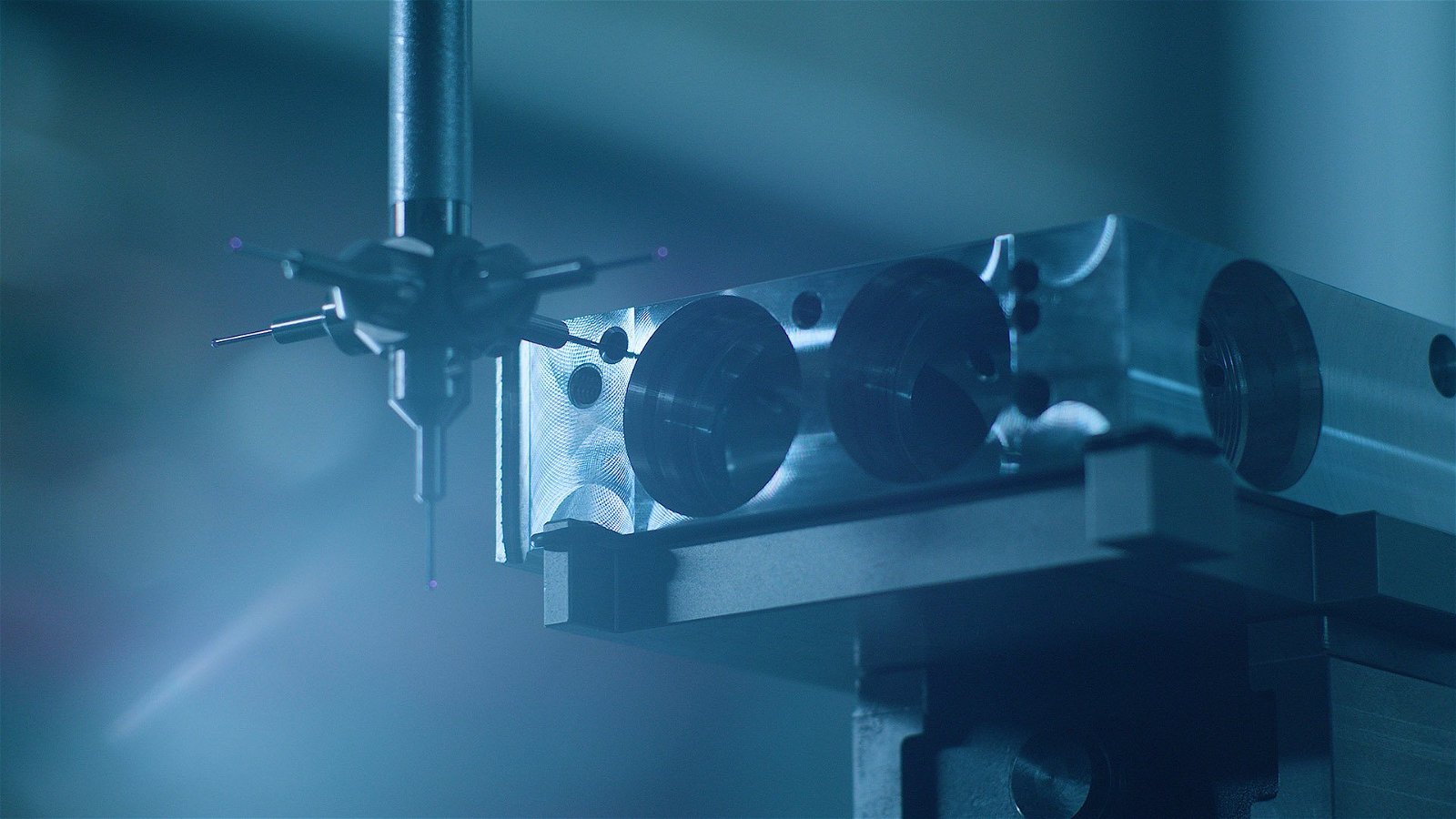

Extreme precision is vital concerning the piston chambers. To ensure a uniform pressure build-up, which is crucial to obtain absolute control over the pivot door movement, the piston chambers and piston should be entirely in line with each other.

To give space to the immense force the system should be able to take, a maximum diameter of the piston chamber is required. At the thinnest part, there is only 2 mm of material available. The drilling should be consistent every time, so all drillings are measured on even the smallest tolerance. In solely this single part of the process, the hinge is checked on more than 60 points, including measurements, hardness, and even the tiniest dents. This will ultimately affect the behavior of the door, making it entirely predictable.

With a high precision quality check of the piston chambers with techniques that are also used for medical equipment like implants, the precision of the drilling and the pistons are tested and confirmed.

What makes up the pivot

The pivot axle is the base of the hinge – the pivot door relies on this part. The axle consists of multiple cam profiles, which determine the movement of the pivot door. The bottom of this part is placed in the floorplate and makes it possible to carry weights up to 500 kg. By creating the pivot axle from high-quality materials, even the most diverse conditions do not affect this system’s operation.

The axle and cam profiles are made of tempered steel for ultimate endurance. The steel is hardened by heating it above 1000 °C, then cooling it down in an exact timeframe. This whole process is done clean and free of oxygen – vacuum. As a consequence, the system is wear-resistant.

The needle bearings quickly and smoothly distribute large forces. They enable fluid damping when the door is op

ened or closed. The well-balanced distribution of the pressure load and smooth distribution of the power makes it possible to open the pivot door with just the touch of a finger.

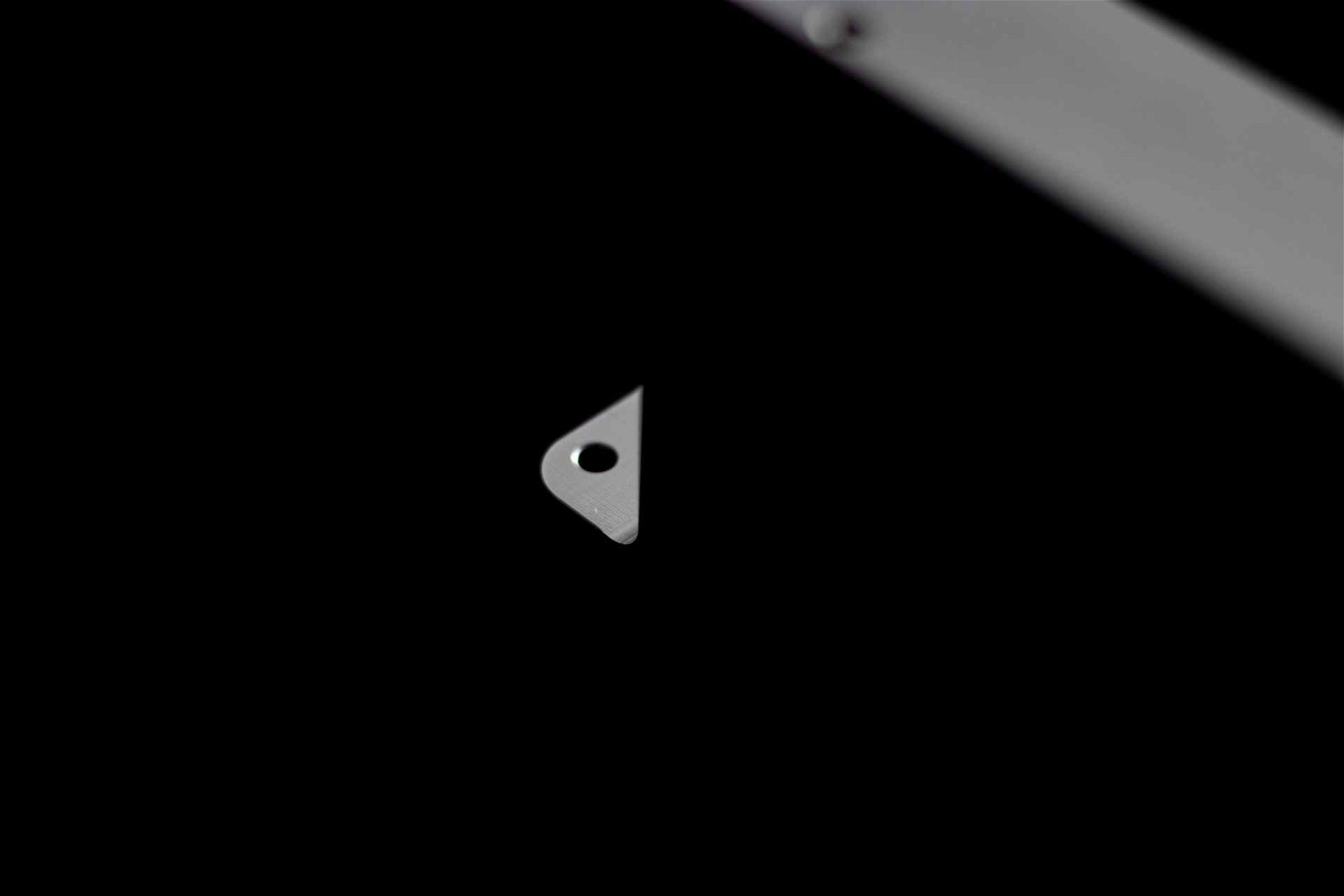

Floor plates

The floorplates for every FritsJurgens pivot hinge system are made out of stainless steel (AISI 420). The steel is hardened in order to withstand the weight of the door and, as it is the only visible part, to ensure the floorplate is scratch-resistant.

The floorplate fasteners only need to be mortised 8 mm into the floor. This makes every FritsJurgens system suitable for all types of floors, including existing floors, and even when radial heating is present. Utilizing strong elastic glue with high tensile, the floor plate is mounted on the floor. Glue chambers ensure a smooth spread for extra ease of installation.

Springs

The FritsJurgens System M and System M+ make use of double spring technology. A stronger spring enables more pressure for the desired force. With the limited space available, a double spring was designed for these systems. Every spring is calibrated to confirm its pressure load.

Hydraulics – power becomes control

Why constrain power when you can convert it into control? FritsJurgens’ technology puts hydraulic power to use by turning it into a controlled, smooth door movement. This is what makes the technology unique. In System M and System M+ the movement of the pivot door is generated and controlled by this technology. In heavy and light doors. Unabridged power, full control.

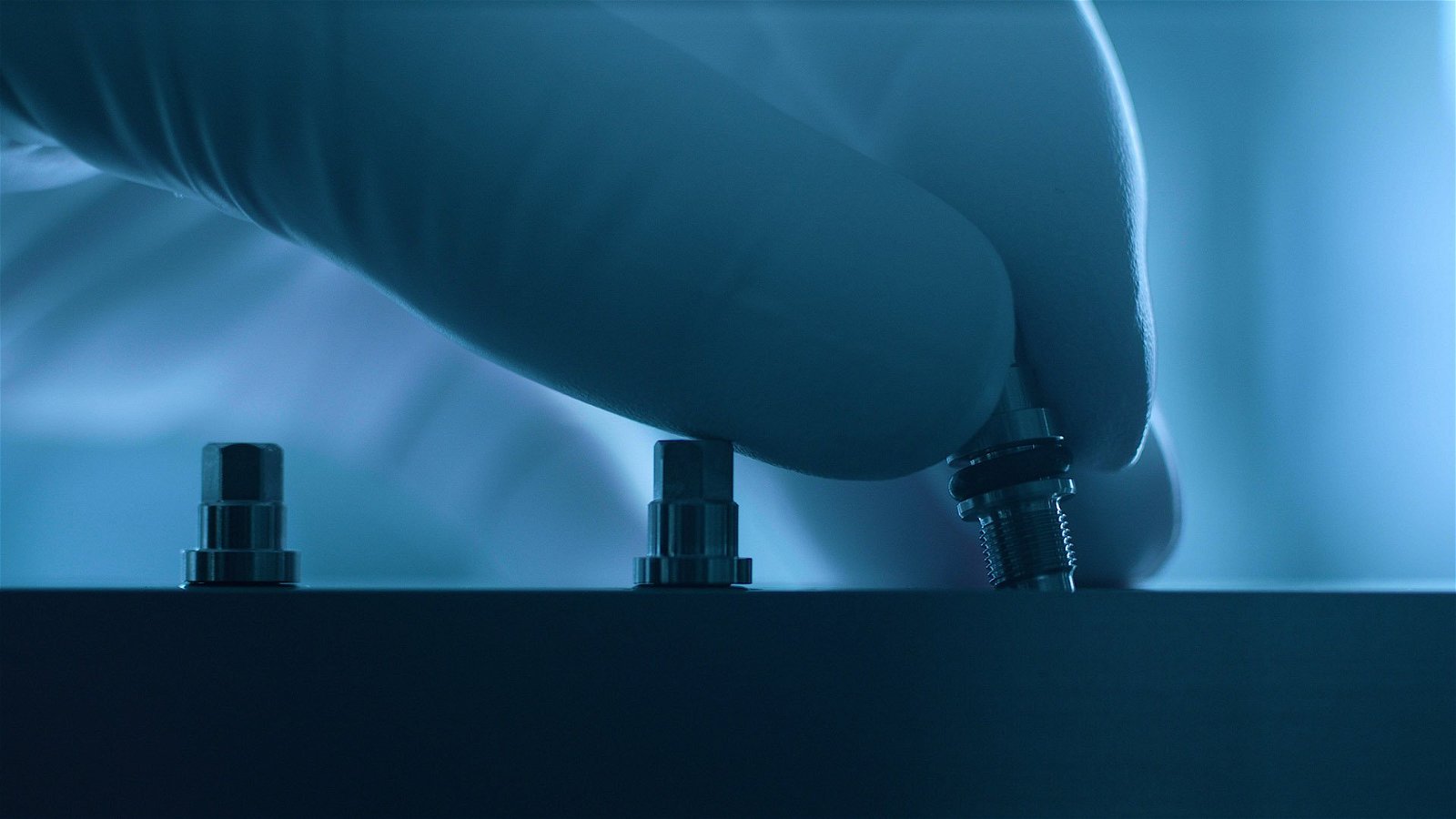

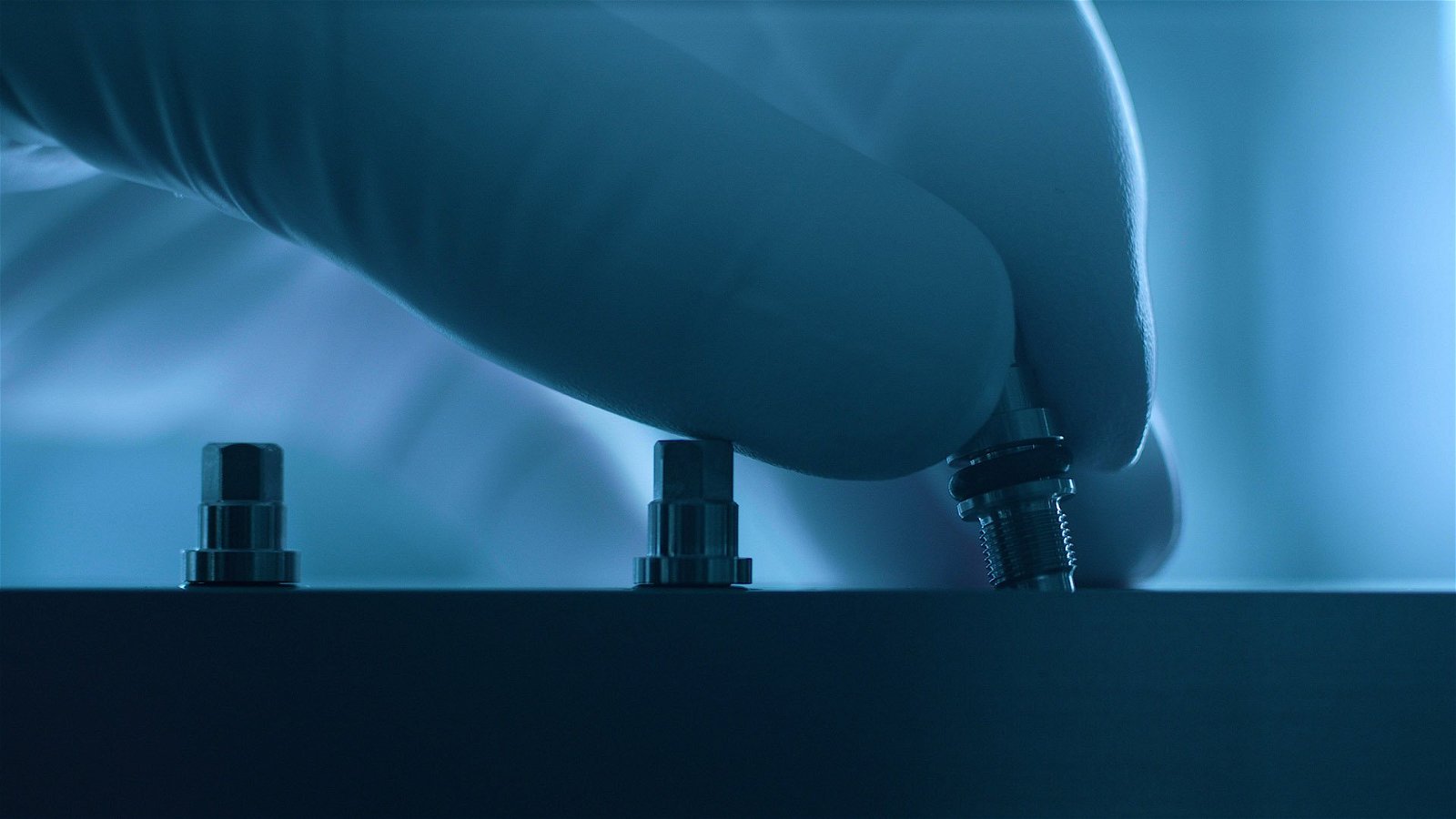

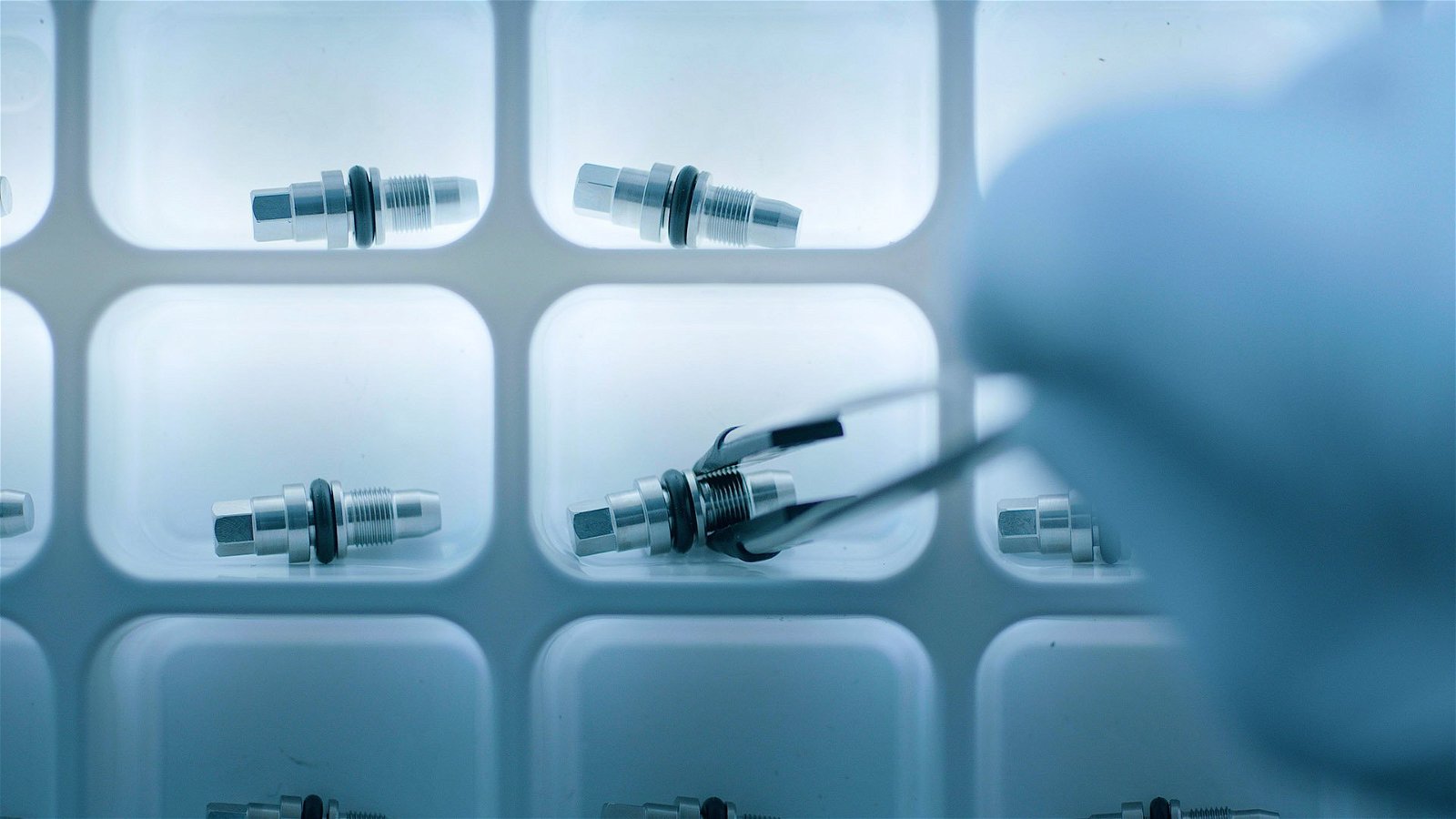

Small things make the difference

The absolute control over the movement of the door is highly dependent on the adjustment-screws. That is why all the screws inside the systems are made in-house. The screws have to be extra small in order to fit inside the systems, while their strength should not be compromised. It is important that they have the exact right feeling to give the customer feedback when finetuning the door movement.

The metric threads on the screws are entirely in line with each other. The screws can be adjusted in such a consistent way that the pivot door’s behaviour becomes very predictable. The precise combination of the depth of the screw and the angle ensure that precisely the right oil pressure is available. The optimum performance and flow of the oil enable the perfect movement of the door.

Testing

A significant part of the hinges’ assembly is done by hand by dedicated professionals to guarantee that every single part of the product meets the quality criteria. When a system is ready, it is tested inside a pivot door before it is shipped to the customer. Every possible step is taken to ensure that the product fulfills its promises.

Revolutionary door solutions

In every part of the process – from a single piece of aluminum to a fully functioning pivot hinge system – FritsJurgens tries to obtain the highest possible quality by combining smart techniques, the best materials, and Dutch craftsmanship. FritsJurgens is dedicated to creating revolutionary door solutions that last a lifetime.